Artificial intelligence (AI) is rapidly redefining how vehicles are conceived, engineered, and manufactured. By infusing every stage of the automotive lifecycle with machine learning, computer vision, and predictive analytics, AI empowers manufacturers to innovate faster, cut costs, and deliver superior quality cars to market.

Revolutionizing Design with Generative Algorithms

In the initial design phase, AI-driven generative design tools take engineers beyond manual sketching. By specifying performance goals—such as weight reduction, structural strength, or aerodynamic drag—designers unleash algorithms that churn out thousands of optimized geometries. These AI-generated concepts often reveal lightweight, high-strength configurations that human intuition might miss, accelerating the shift from idea to prototype while minimizing material waste.

Accelerating Validation through Smart Simulation

Traditionally, validating a new component required lengthy physical testing. Today, AI-enhanced simulation platforms drastically shorten this cycle. Machine learning “surrogate” models, trained on extensive archives of past simulations, predict stress distributions and fluid flows in seconds rather than hours. This rapid iteration enables engineers to fine-tune designs early, reducing reliance on costly prototypes and slashing development time.

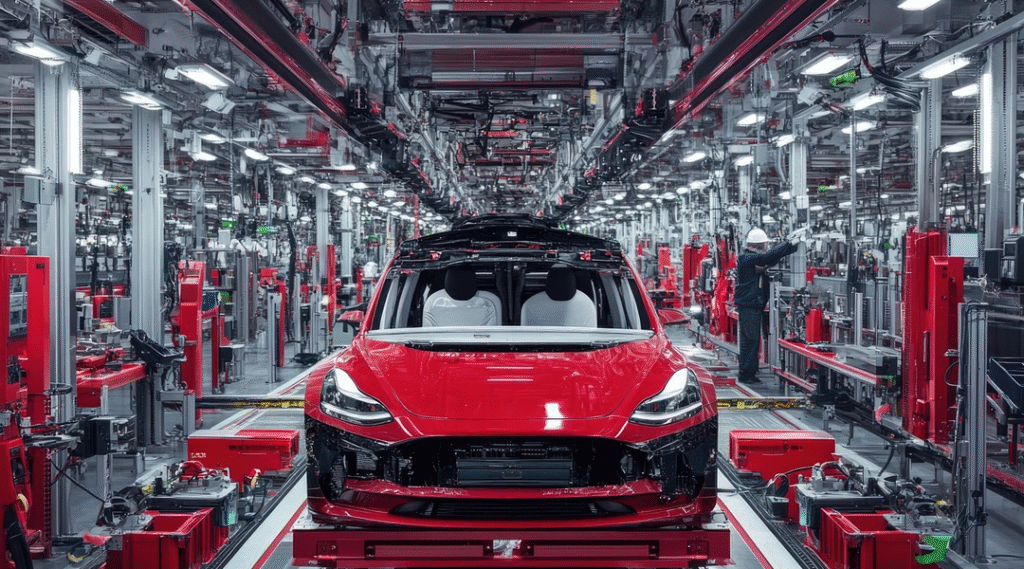

Building Smarter Factories with IIoT and Computer Vision

On the production floor, AI intertwines with the Industrial Internet of Things (IIoT) to create adaptive, self-optimizing assembly lines. Deep-learning-powered cameras inspect weld seams, paint finishes, and panel gaps in real time, catching microscopic defects before they escalate. Meanwhile, robotic arms endowed with reinforcement learning discover the most efficient motion patterns, seamlessly switching between different vehicle models or custom options. The result is higher throughput, fewer rejects, and more flexible production workflows.

Optimizing Supply Chains with Predictive Analytics

Auto manufacturers grapple with complex global supply networks. AI platforms ingest live data from suppliers, shipping partners, and market forecasts to forecast part demand, flag supply disruptions, and suggest alternative sourcing strategies. During unexpected events—such as raw-material shortages or logistic delays—AI-driven scenario planning helps teams respond swiftly, ensuring just-in-time delivery and minimizing inventory carrying costs.

Preventing Downtime via Predictive Maintenance

Equipment failures on the line can bring production to a halt. To combat this, AI algorithms analyze vibration, temperature, and acoustic data from sensors embedded in presses, lathes, and conveyors. By detecting subtle deviations that precede mechanical issues, predictive-maintenance systems notify technicians to perform targeted interventions before breakdowns occur. This proactive approach boosts overall equipment effectiveness (OEE) and saves millions in downtime-related losses.

Powering Next-Generation Driver Assistance and Autonomy

AI’s influence extends well beyond the factory walls. Developing advanced driver-assistance systems (ADAS) and autonomous vehicles hinges on training deep neural networks to interpret camera feeds, LIDAR point clouds, and radar scans. Massive, labeled datasets allow these networks to recognize pedestrians, signage, and road conditions with high accuracy. Continuous learning pipelines feed back rare “edge cases” from vehicles in service, enabling models to evolve and handle ever-more complex traffic scenarios safely.

Enhancing Validation with Digital Twins and Immersive Testing

Digital twins—virtual replicas of vehicles and manufacturing lines—paired with AI make testing and validation more efficient. Engineers and human-factors specialists don VR or AR headsets to navigate simulated assembly environments, interact with in-vehicle controls, and assess ergonomics. AI agents within these simulations mimic real-world conditions, providing rapid feedback on user interfaces, assembly procedures, and maintenance operations.

Delivering Personalized Vehicles at Scale

Today’s drivers expect customization, whether it’s exclusive color palettes, bespoke interiors, or tailored software features. AI-enabled configuration tools analyze customer preferences alongside production constraints to generate optimized build plans. This mass-customization capability balances individualization with economies of scale, letting manufacturers offer a suite of unique options without compromising efficiency.

Toward a Sustainable, Efficient Future

Beyond cost and speed advantages, AI contributes significantly to sustainability. Optimized designs reduce material consumption and vehicle weight, enhancing fuel efficiency or electric range. Predictive energy-management systems in smart factories minimize power spikes and coordinate renewable energy use. In logistics, AI-backed route planning for inbound and outbound shipments shrinks carbon footprints.

The integration of AI across design, prototyping, manufacturing, supply chain management, and vehicle validation is revolutionizing the automotive sector. By automating complex analyses, enabling real-time quality control, and fostering continuous learning, AI not only accelerates development cycles but also elevates product quality and sustainability. Automakers that embrace these intelligent tools will be best positioned to navigate the industry’s rapid evolution and meet the exacting demands of tomorrow’s drivers. As AI continues to advance, its role in driving automotive innovation will only deepen—propelling the industry toward a smarter, more efficient future.

More about the Automotive Topic:

Emerging Trends & Innovation in the Automotive Aftermarket

Driving the Future: Technology and Digital Transformation in the Automotive Aftermarket

Deep Analyses of Parts & Service Segmentation in the Automotive Aftermarket

As for in-depth insight articles about AI tech, please visit our AI Tech Category here.

As for in-depth insight articles about Auto Tech, please visit our Auto Tech Category here.

As for in-depth insight articles about Smart IoT, please visit our Smart IoT Category here.

As for in-depth insight articles about Energy, please visit our Energy Category here.

If you want to save time for high-quality reading, please visit our Editors’ Pick here.