Artificial intelligence (AI) and additive manufacturing have long evolved on parallel tracks, but 2025 is shaping up to be the year they truly converge. By embedding machine‑learning models into every stage of the digital‑to‑physical pipeline—design, preparation, build, and post‑processing—AI is transforming 3D printing from a largely trial‑and‑error craft into a data‑driven, autonomous production technology. The result: higher part quality, faster iteration, lower cost per unit, and business models that were impossible just a few years ago.

1. Generative Design: Letting Algorithms Think Outside the Box

Traditional CAD relies on human intuition; generative design flips that script. AI algorithms take a designer’s functional constraints (weight, strength, thermal load, etc.) and iterate through thousands of topology variations in hours—far more than a human team could evaluate in weeks.

- Lighter, stronger parts: Aerospace firms report weight reductions of 30–50 % while meeting stringent safety margins.

- Material savings: Optimized lattices often cut material consumption by double‑digit percentages, lowering both cost and CO₂ footprint.

- Faster time‑to‑market: Engineers validate only the top AI‑ranked candidates, reducing the overall design cycle.

2. Adaptive Slicing & Toolpath Optimization

Slicing software converts 3D geometry into machine instructions, but uniform layer heights waste time where fine detail isn’t needed. AI‑based adaptive slicing engines analyze curvature, critical features, and stress zones to vary layer thickness automatically:

- Print up to 40 % faster on non‑critical walls without losing resolution on fine details.

- Reduce support structures by predicting overhang stability, saving post‑processing hours.

- Automatic parameter tuning—temperature, speed, infill, and cooling—based on historical success rates and real‑time sensor feedback.

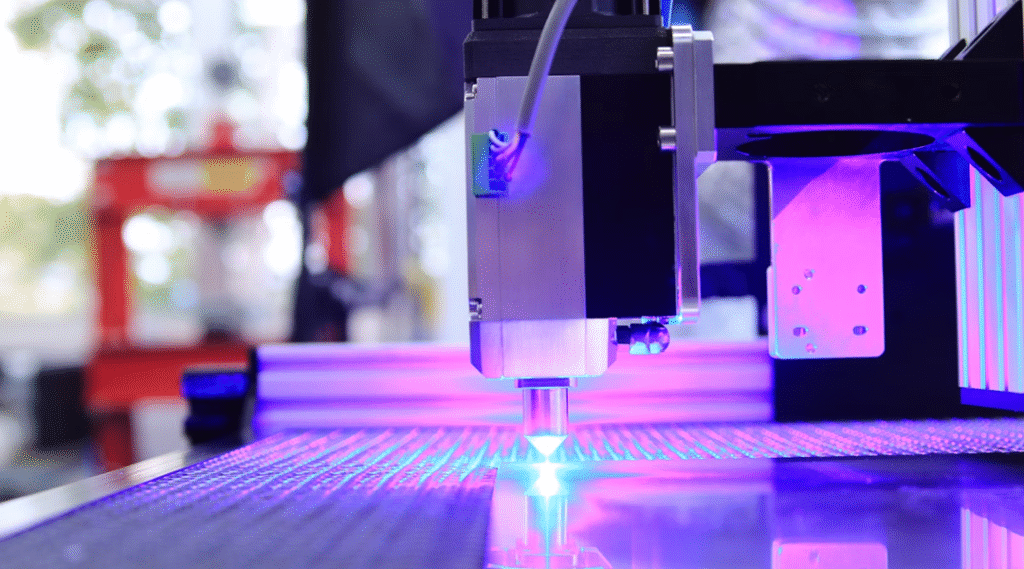

3. In‑Process Monitoring & Predictive Quality Control

Machine‑vision cameras, lasers, and thermal sensors now stream gigabytes of data during each build. Deep‑learning models analyze melt‑pool dynamics, layer fusion, and surface roughness on the fly. When anomalies such as porosity or warping cross threshold levels, the printer can:

- Pause and self‑correct—adjusting laser power or extrusion temperature.

- Alert technicians before scrap material is wasted.

- Update its model so the next build improves automatically.

Plants running predictive quality control report scrap rates dropping by 20–50 %, which cascades into lower energy use and shorter delivery schedules.

4. Self‑Healing Maintenance Schedules

Downtime is the bane of every additive manufacturing facility. AI‑powered predictive‑maintenance platforms crunch sensor logs—vibration, motor current, nozzle pressure—to foresee failures days or weeks ahead. Maintenance crews receive a prioritized task list, spare parts are pre‑ordered, and unexpected stoppages decline dramatically.

5. Supply‑Chain & Business‑Model Disruption

AI‑enabled 3D printing is not just technical; it’s strategic:

- Digital inventories: Instead of warehousing spares, companies store encrypted build files. AI verifies the right part, in the right revision, for on‑demand production near the point of use.

- Mass customization at scale: Machine‑learning recommendation engines pair customer data with parametric models, auto‑configuring products—think orthodontic aligners or athletic shoe midsoles—without manual design work.

- Circular manufacturing: AI tracks part genealogy and material composition, making recycling or refurbishment decisions autonomous.

6. Challenges and Ethical Considerations

- Data security: Generative designs and process data are valuable IP; secure cloud workflows and zero‑trust architectures are mandatory.

- Model bias: Training datasets must reflect diverse geometries and materials to prevent systematic errors.

- Skills gap: Engineers need upskilling in data science and AI literacy to fully exploit these tools.

An Intelligent, End‑to‑End Manufacturing Paradigm

AI is rapidly transforming 3D printing from a prototyping aid into an intelligent, end‑to‑end manufacturing paradigm. Companies that integrate machine learning into design, production, and maintenance are already slashing lead times and unlocking revenue streams unimaginable in the subtractive era. As algorithms continue to learn and printers become more autonomous, the line between digital intent and physical reality will grow ever thinner—reshaping not just how we make things, but how we imagine them in the first place.

As for AI and manufacturing, you may learn more from these two article: “Collaborative Robots: The Cornerstone of Tomorrow’s Manufacturing” and “Industry 4.0 Unleashed: How AI Is Revolutionizing Manufacturing“

As for in-depth insight articles about AI tech, please visit our AI Tech Category here.

As for in-depth insight articles about Auto Tech, please visit our Auto Tech Category here.

As for in-depth insight articles about Smart IoT, please visit our Smart IoT Category here.

As for in-depth insight articles about Energy, please visit our Energy Category here.

If you want to save time for high-quality reading, please visit our Editors’ Pick here.