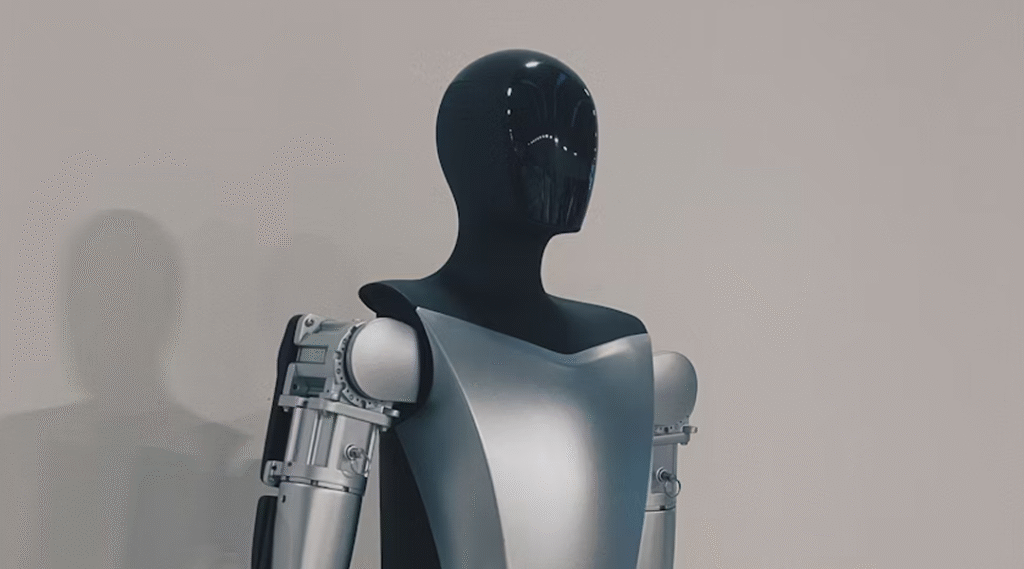

Since its unveiling on AI Day 2022, Tesla’s humanoid robot “Optimus” has captured headlines with grandiose promises: a general-purpose, bipedal automaton capable of mundane factory tasks and, someday, household chores. As the company renowned for electric vehicles and full‑self‑driving ambitions extends its reach into robotics, two key questions arise: Does Optimus represent the most advanced robotic technology today, and can it legitimately lead the broader robotics industry? In this analysis, we’ll explore Optimus’s technological breakthroughs, compare it with leading competitors, and evaluate Tesla’s path to market dominance.

Technological Foundations: AI, Sensing, and Actuation

At the heart of Optimus lies Tesla’s proprietary AI stack, evolved from its Autopilot and FSD (Full Self‑Driving) neural networks. These networks power high‑dimensional perception—processing real‑time video feeds from multiple cameras, fusing them with inertial data to map three‑dimensional spaces. Unlike many research‑lab robots that rely heavily on lidar or external motion‑capture systems, Optimus leans into computer vision and battery‑optimized compute units, leveraging Tesla’s Dojo chip architecture for on‑board inference.

On the actuation front, Optimus features custom electric motors designed for efficiency and torque density. These brushless, liquid‑cooled actuators drive the robot’s 28 degrees of freedom, enabling human‑like joint articulation. Early prototypes demonstrated a smooth gait at walking speeds up to 5 km/h and the ability to carry modest payloads—milestones for a first‑generation platform.

Software Advantage: Data Scale and Continuous Learning

Tesla’s distinguishing advantage is data scale. With over a million EVs gathering camera and sensor data across millions of miles driven daily, Tesla has built a vast training corpus for its neural nets. When applied to robotics, this data pipeline promises continuous improvement: every factory deployment, prototype test, or home‑use scenario can theoretically feed back into the model‑training loop. Contrast this to competitors like Boston Dynamics, which rely on expensive, small‑batch trials and manual labeling. Tesla’s vision is to create a self‑improving system that learns from every interaction.

Manufacturing and Cost: From Prototype to Production

Robotic startups often falter at the manufacturing cliff—moving from lab‐scale builds costing hundreds of thousands per unit to mass production at consumer‐friendly price points. Tesla’s vertically integrated Gigafactory model, established supply chains for batteries and electronics, and proven scale‐up playbook give Optimus a potential cost edge. CEO Elon Musk has set ambitious targets: to produce “millions” of Optimus units at a per‐unit cost comparable to high‐end luxury cars within a decade. While these goals remain untested, Tesla’s automotive track record suggests it may achieve orders‐of‐magnitude cost reductions faster than specialized robotics firms.

Competitive Landscape: Boston Dynamics, Agility, and Others

Boston Dynamics’ Atlas robot enjoys notoriety for its exceptional agility—backflips, parkour, and dynamic balancing that Tesla’s early prototypes have not matched. Agility Robotics’ Digit offers a modular, warehouse‐optimized platform already in pilot deployments for logistics. Industrial arms from Fanuc, ABB, and KUKA excel in precision and reliability in highly structured environments. Compared to these, Optimus is broader in scope but still relatively limited in specialized capabilities. In raw agility, strength, or industrial repeatability, Optimus prototypes have yet to surpass incumbents. Its advantage lies in ambition and integration rather than niche excellence.

Use Cases and Early Deployments

Thus far, Tesla has demonstrated Optimus performing elementary tasks: lifting boxes, pressing buttons, and carrying tools across a flat floor. More compelling is the vision of humanoid robots replacing cost‑sensitive labor in manufacturing and distribution centers. Tesla itself plans to deploy Optimus on its own assembly lines, using them for non‑value‑added tasks like parts transfer and simple inspections. Real‑world pilot programs at Gigafactories will be critical tests: can Optimus achieve uptime, reliability, and safety metrics comparable to industrial robots at a competitive cost of ownership?

Challenges Ahead: Robustness, Regulation, and Public Perception

Transitioning from controlled factory settings to unstructured human environments exposes myriad challenges: fall recovery, soft object manipulation, battery longevity, and robust fail‑safe systems. Safety regulations for domestic robots are still evolving, and public trust in humanoid machines remains fragile. A single high‐profile accident or malfunction could trigger regulatory backlash, slowing deployments. Tesla’s track record with over‑the‑air updates and centralized data gathering offers advantages in rapid bug fixes—but it also invites scrutiny over remote control and cybersecurity vulnerabilities.

Roadmap to Leadership: What Success Looks Like

For Optimus to lead the industry, Tesla must achieve three milestones:

- Performance Parity: Demonstrate sustained, 24/7 operation in real‑world industrial settings, matching or exceeding specialist robots in uptime and throughput.

- Cost Competitiveness: Drive manufacturing costs down to the range of $20,000–$30,000 per unit, making deployment economically attractive relative to human labor in target markets.

- Ecosystem Integration: Build a developer platform and marketplace for customized robotics applications, leveraging Tesla’s AI expertise and Dojo infrastructure to attract third‐party innovation.

Vision vs. Reality

In its current form, Tesla Optimus is not yet the most advanced robot in every technical dimension—Boston Dynamics still holds the agility crown, and specialized industrial arms remain unrivaled in precision. However, Tesla’s strengths in AI scale, manufacturing prowess, and integrated software/hardware ecosystems position Optimus as a potentially transformative force. If Tesla can translate prototype demonstrations into reliable, cost‑effective production units—and foster a vibrant application ecosystem—Optimus may indeed lead the next wave of robotic automation, reshaping both factories and daily life. Until then, it remains an ambitious contender whose ultimate impact hinges on execution as much as on groundbreaking vision.

More articles about Tesla:

Humanoid Robotics Face-Off: Assessing Tesla Optimus and Its Top Competitors

Elon Musk’s Master Blueprint for Tesla

Why Tesla Embraced Pure Vision for Self‑Driving Supremacy

Is Tesla’s Self-Driving Technology Reliable? A Comprehensive Analysis

As for in-depth insight articles about AI tech, please visit our AI Tech Category here.

As for in-depth insight articles about Auto Tech, please visit our Auto Tech Category here.

As for in-depth insight articles about Smart IoT, please visit our Smart IoT Category here.

As for in-depth insight articles about Energy, please visit our Energy Category here.

If you want to save time for high-quality reading, please visit our Editors’ Pick here.