Battery monitoring has evolved from a simple protection layer into a core competency for electric vehicles (EVs). Modern Battery Management Systems (BMS) must do more than measure voltage and current — they must accurately estimate usable energy, detect early degradation, manage cell balance and temperature, and feed reliable telemetry for fleet-level prognostics. Success depends on blending sensing hardware, physics-based and data-driven models, thermal design, and secure, standards-compliant software.

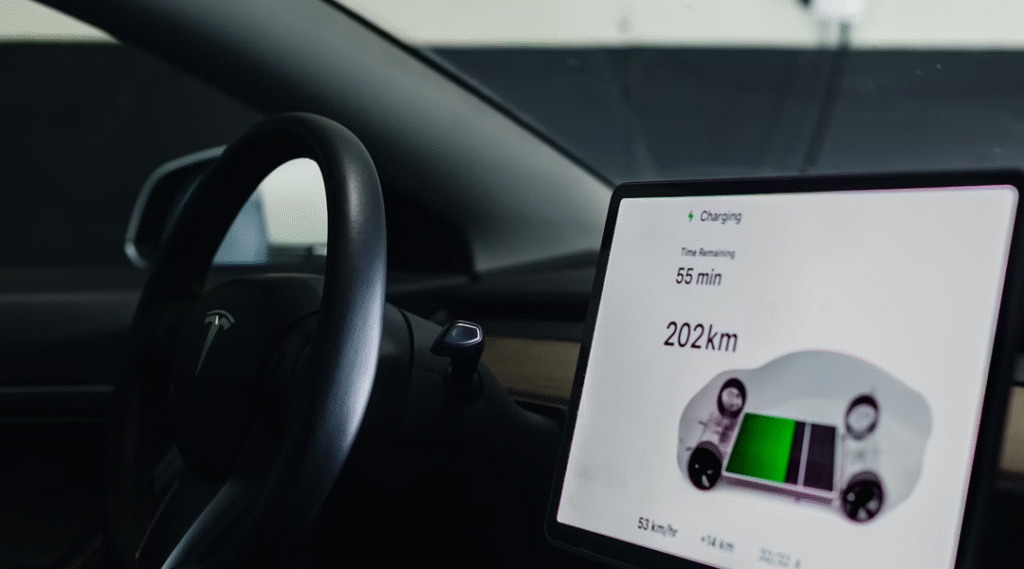

At the foundation are two operational questions every BMS must answer: how much energy remains (State of Charge, SOC) and how healthy the pack is (State of Health, SOH). Basic techniques like coulomb counting suffer from drift and transient errors; voltage-only methods fail under load and temperature swings. To remain accurate across real-world driving profiles, contemporary systems fuse multiple approaches — equivalent-circuit models, Kalman-filter variants, and machine-learning corrections — producing hybrid estimators that adapt to nonlinear behavior while constraining error growth.

Sensing fidelity is the next frontier. Beyond voltage, current, and spot temperature sensors, emerging designs incorporate impedance-based diagnostics. Electrochemical Impedance Spectroscopy (EIS) and runtime impedance monitoring reveal internal degradation and subtle loss-of-capacity signatures earlier than voltage trends alone. When integrated periodically or opportunistically during low-load states, impedance measures significantly improve SOH estimations and enable smarter warranty and second-life decisions. However, impedance sensing adds complexity: measurement timing, signal injection strategies, and calibration routines must be carefully engineered to avoid interfering with vehicle operation.

Thermal and balancing strategies are deeply coupled with monitoring quality. Temperature non-uniformity across a pack skews SOC/SOH models and accelerates aging. Distributed temperature sensing — or at least a model that infers intra-pack gradients — is essential where high power or rapid charging is common. Likewise, cell balancing choices shape usable capacity. Passive balancing is cheap and simple but wastes energy; active balancing reduces long-term capacity loss and increases usable range, particularly for high-energy-density packs or vehicles that cycle frequently. The BMS must therefore orchestrate balancing decisions with monitoring insights to maximize lifecycle value.

Safety, regulatory compliance, and cybersecurity create hard constraints. Functional-safety processes (e.g., ISO 26262) require fault-detection paths that are auditable and meet required integrity levels, while vehicle cybersecurity standards demand authenticated, tamper-resistant telemetry and secure over-the-air update mechanisms. Monitoring functions must be designed so fault detection, isolation, and mitigation work under ASIL constraints and do not open attack surfaces. This frequently drives architectural choices such as redundant sensing, fail-safe states, and cryptographic protection for offboard communication.

Data and cloud integration expand monitoring from a vehicle-level service to a lifecycle platform. Aggregated fleet telemetry enables remaining useful life (RUL) models, trend-based maintenance, and optimized warranty provisions. The trade-offs are real: transmitting fine-grained telemetry consumes bandwidth and raises privacy concerns, while too-limited reporting weakens prognostics. An edge-first approach — running real-time safety checks locally while uploading summarized or event-driven telemetry — balances immediacy and analytics needs.

Several practical challenges persist. Low-cost sensors drift and need calibration plans or redundancy; model drift requires periodic re-identification or self-calibrating estimators; measurement noise and heterogeneity across cell chemistries complicate one-size-fits-all algorithms. Commercial systems must also justify added cost and weight for active balancing or impedance hardware against the real-world value unlocked by longer life and fewer warranty claims.

Recommendations for OEMs and suppliers:

- Adopt hybrid SOC/SOH estimators combining physics-based models with adaptive ML corrections.

- Invest in impedance-aware sensing roadmaps for early degradation detection, prioritized for high-energy and warranty-sensitive platforms.

- Design thermal models and distributed sensing into the pack architecture from the start.

- Build monitoring with safety and security by design — include redundancy, secure telemetry, and OTA update integrity.

- Use edge-first telemetry: real-time local protection plus selective cloud uploads for prognostics.

In short, battery monitoring is now a multidisciplinary engineering challenge that fuses electrochemistry, control theory, thermal management, and data science. The most competitive BMS platforms will be modular, impedance-aware, and secure — able to provide precise SOC/SOH estimates, extend usable life through intelligent balancing and thermal control, and feed analytics ecosystems that turn fleet data into actionable lifecycle value. Those capabilities will determine not only the reliability of a vehicle today, but how economically and safely its battery can be managed across years of service and eventual second-life uses.

As for more for Auto Tech information, please visit our professional auto tech section here.

More for the topic:

How the Public Benefits from Autonomous Driving Technologies

Why We Should Trust Self-Driving Technologies: A Comprehensive Exploration

Driving Tomorrow: The Hottest Auto Tech Trends of 2025

Empowering Everyday Drivers: How AI Is Transforming the Driving Experience