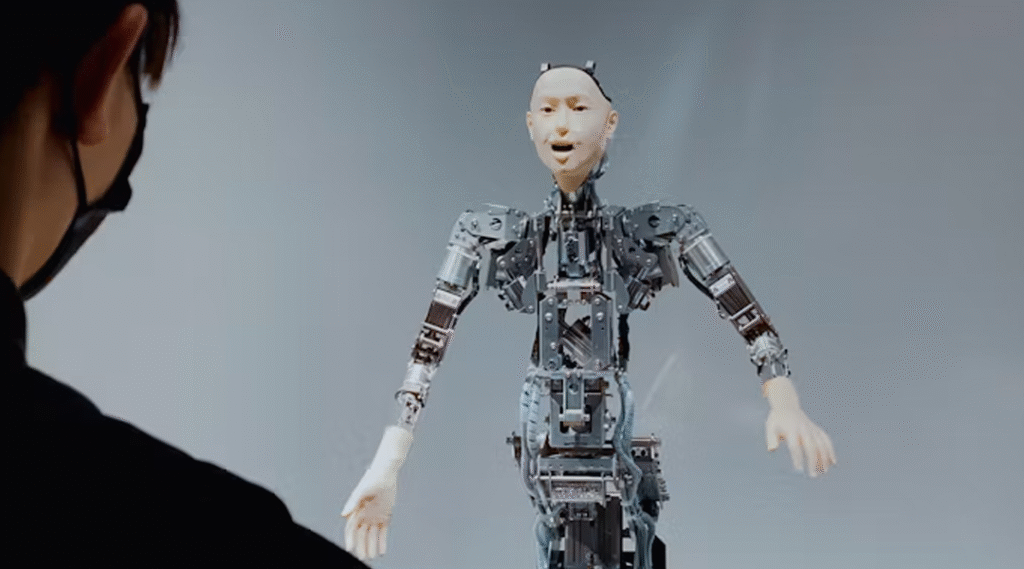

From autonomous warehouse forklifts to social robots in hospitality, modern robotic systems increasingly rely on Internet of Things (IoT) technologies to perceive, decide, and act with unprecedented agility. By integrating smart sensors, low‑power connectivity, edge computing, and cloud analytics, IoT lays the foundation for robotics that are more adaptable, scalable, and intelligent than ever before. This article explores the key IoT building blocks that empower today’s robots and chart the course for tomorrow’s innovations.

1. Ubiquitous Connectivity and Interoperability

At the heart of any IoT‑enabled robot lies a robust networking layer. Protocols like Wi‑Fi 6, Bluetooth Low Energy, Zigbee, and emerging LPWAN standards (LoRaWAN, NB‑IoT) facilitate seamless, low‑latency exchanges between robots, sensors, and control hubs. This mesh of connections allows fleets of robots to coordinate tasks—whether moving pallets in a fulfillment center or mapping rugged outdoor terrain—while maintaining reliable links even in RF‑noisy environments. Standardized APIs and middleware (e.g., MQTT, OPC UA) ensure devices from diverse vendors can interoperate, reducing integration costs and accelerating deployment.

2. Smart Sensor Networks for Rich Perception

Robots depend on an array of IoT sensors—cameras, lidar, ultrasonic rangefinders, temperature and humidity monitors, vibration and pressure gauges—to build an accurate, real‑time model of their surroundings. Distributed sensor nodes scattered throughout a facility or embedded in infrastructure feed telemetry into robotic control loops, enabling dynamic obstacle avoidance, precision gripping, and adaptive navigation. For example, an agri‑robot can adjust its harvesting path based on soil moisture data from IoT probes, maximizing yield while preserving plant health.

3. Edge Computing and On‑Device AI

While raw sensor streams are invaluable, transmitting vast volumes of data to the cloud for processing can introduce prohibitive latency and bandwidth costs. Edge‑IoT platforms remedy this by embedding compute capability directly on robots or at local gateways. Lightweight inferencing engines—using models optimized via quantization and pruning—execute computer‑vision algorithms, path‑planning routines, and anomaly detection in milliseconds. This on‑device intelligence lets robots respond in real time to dynamic conditions, maintain safety around humans, and continue operating autonomously when network links degrade.

4. Cloud Platforms and Big Data Analytics

The cloud serves as the central nervous system for large‑scale robotic deployments, aggregating data from distributed assets to drive training, fleet orchestration, and predictive maintenance. Historical logs of machine performance, sensor anomalies, and task efficiency feed machine‑learning pipelines that refine control policies, optimize traffic flows, and predict component failures days or weeks before they occur. End‑to‑end IoT platforms from AWS, Azure, and Google Cloud provide built‑in support for device provisioning, over‑the‑air (OTA) updates, and role‑based access control—ensuring security and compliance at industrial scale.

5. Digital Twins and Simulation Environments

IoT technologies bridge the physical and virtual worlds through digital twins—real‑time, software‑based replicas of robotic systems and their operating contexts. By mirroring sensor feeds, actuator states, and environmental variables, digital twins enable developers to simulate new behaviors, validate control algorithms, and stress‑test failure scenarios without risking hardware damage. When integrated with IoT data streams, these simulations accelerate go‑to‑market cycles, reduce costly field trials, and support “what‑if” analyses for layout changes, software upgrades, or new payload integrations.

6. Collaborative Swarms and Orchestration

The scalability of IoT underpins the rise of multi‑robot swarms, where dozens—or even hundreds—of robots collaborate to tackle large‑scale tasks. Each unit shares status updates and task assignments over a lightweight IoT fabric, while centralized or decentralized orchestrators dynamically balance workloads, reroute units around bottlenecks, and adapt to changes in demand. Such coordinated systems excel in applications like warehouse fulfillment, last‑mile delivery, and environmental monitoring—yielding efficiencies that single robots cannot achieve alone.

7. Security, Compliance, and Lifecycle Management

As robots become critical business assets, robust IoT security measures—device attestation, encrypted communication channels, and continuous vulnerability scanning—guard against tampering and cyberattacks. Integrated identity‑and‑access solutions ensure only authorized personnel and systems can issue commands or access sensitive data. Furthermore, IoT device management frameworks automate lifecycle tasks—firmware patches, certificate rotations, and health checks—minimizing downtime and ensuring regulatory compliance in sectors like healthcare and manufacturing.

Next‑Generation Robotics

By weaving together smart connectivity, sensor fusion, edge intelligence, cloud analytics, and rigorous security, IoT technologies furnish the essential infrastructure for next‑generation robotics. This synergistic alliance not only augments autonomy and resilience but also unlocks new business models—from Robotics‑as‑a‑Service to predictive maintenance subscriptions—propelling robotics from niche use cases into the mainstream. As IoT standards mature and compute capabilities continue to shrink, the robots of tomorrow will be ever more connected, context‑aware, and capable of seamlessly integrating into our homes, workplaces, and cities.

More for Robotics:

Connected Intelligence: How Smart IoT Technologies Underpin the Future of Robotics

As for in-depth insight articles about AI tech, please visit our AI Tech Category here.

As for in-depth insight articles about Auto Tech, please visit our Auto Tech Category here.

As for in-depth insight articles about Smart IoT, please visit our Smart IoT Category here.

As for in-depth insight articles about Energy, please visit our Energy Category here.

If you want to save time for high-quality reading, please visit our Editors’ Pick here.