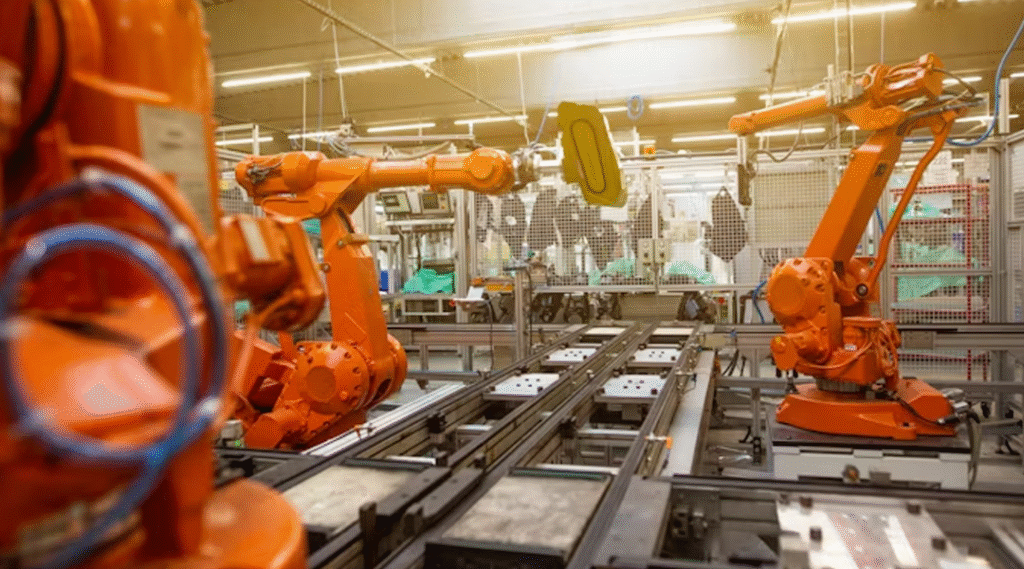

As manufacturing and service sectors evolve beyond mere automation and data-driven optimization, a new paradigm—Industry 5.0—is emerging. Where Industry 4.0 focused on smart factories, the Industrial Internet of Things (IIoT), and big‑data analytics, Industry 5.0 brings humans back to the center of the production process, emphasizing collaboration between skilled workers, advanced robotics, and AI. But is Industry 5.0 already here? And how can companies catch up—or even lead—the charge?

Defining Industry 5.0

Industry 5.0 pivots from pure efficiency toward resilience, personalization, and sustainability. Its three core pillars are:

- Collaborative Intelligence – Human‑centric workplaces where employees and cobots (collaborative robots) jointly perform complex tasks.

- Mass Personalization – Custom products at near‑mass‑production scale, enabled by flexible manufacturing cells.

- Circularity and Sustainability – Closed‑loop systems minimizing waste and carbon footprint, integrating renewable energy and circular‑economy principles.

Indicators That Industry 5.0 Is Underway

- Investment Growth

– Global investment in cobots reached US $2.1 billion in 2023, up 35% year‑over‑year, and is projected to top US $4.5 billion by 2027.

– Spending on human‑machine interface technologies (augmented reality wearables, haptic controls) is forecast at US $1.7 billion in 2025, climbing to US $3.2 billion by 2030. - Adoption Rates

– In a 2024 survey of 500 manufacturers, 62% reported deploying at least one cobot application, and 48% plan to expand cobot use by 2026.

– 41% of leading firms have begun pilot programs for personalized production lines that can switch SKUs in under five minutes. - Sustainability Mandates

– Regulatory pressure is rising: over 70% of Fortune 500 firms have announced net‑zero targets by 2040, prompting investment in circular‑economy solutions.

– Recycling‑and‑remanufacturing initiatives now account for 12% of total industrial-capital expenditure, up from just 4% five years ago.

These numbers underscore a clear shift: companies are moving from rigid assembly‑line automation to adaptive, human‑augmented systems.

Strategies to Catch Up and Lead

1. Upskill for Human–Robot Collaboration

Invest in workforce development with an emphasis on digital literacy and robot‑management skills. Offer certification programs in cobot operation and maintenance. A recent industry study showed that manufacturers investing at least 3% of payroll in upskilling saw a 25% faster adoption of next‑gen technologies.

2. Adopt Flexible, Modular Production

Reconfigure factories into small, standardized workcells that can be rapidly retooled. Implement plug‑and‑play robotics and quick‑change tooling systems. Firms that transitioned to modular production witnessed a 20% reduction in changeover time and a 15% increase in on‑time delivery rates.

3. Leverage AI for Personalized Manufacturing

Use AI‑driven scheduling and quality‑control algorithms to enable batch sizes of one at scale. Incorporate digital‑twin simulations to test new product variants virtually. Early adopters of AI personalization reported a 30% premium on custom‑product pricing and a 10% uplift in customer loyalty metrics.

4. Embed Circular‑Economy Principles

Implement closed‑loop supply chains by designing products for disassembly and using recycled feedstocks. Track material flows with blockchain‑based provenance systems. Organizations that integrated circular practices reduced raw‑material costs by 18% and cut waste disposal fees by 22%.

5. Forge Ecosystem Partnerships

No single company can master every facet of Industry 5.0. Form alliances with robotics vendors, software startups, and sustainability consultancies. Co‑innovation hubs—where OEMs, universities, and technology partners collaborate—have accelerated pilot‑to‑production timelines by an average of 40%.

The Competitive Edge

Industry 5.0 is not simply about upgrading technology; it’s a strategic reinvention of how people and machines co‑create value. Companies that proactively blend human ingenuity with robotic precision, embrace data‑driven personalization, and anchor operations in sustainable practices will differentiate themselves. As investment in collaborative robotics and human‑centered interfaces accelerates, late adopters risk falling behind—both in cost structure and in the ability to respond to rapidly shifting customer demands.

By committing to upskilling, modular flexibility, AI‑enhanced personalization, circular‑economy designs, and cross‑industry partnerships, forward‑thinking firms can not only catch up but lead the Industry 5.0 revolution—transforming manufacturing from a monologue of machines into a dialogue between humans and intelligent systems.

As for the relative topics, you may also like:

Collaborative Robots: The Cornerstone of Tomorrow’s Manufacturing

Industry 4.0 Unleashed: How AI Is Revolutionizing Manufacturing

Data Center: Cloud, On-Premises, and Hybrid Infrastructure

As for in-depth insight articles about AI tech, please visit our AI Tech Category here.

As for in-depth insight articles about Auto Tech, please visit our Auto Tech Category here.

As for in-depth insight articles about Smart IoT, please visit our Smart IoT Category here.

As for in-depth insight articles about Energy, please visit our Energy Category here.

If you want to save time for high-quality reading, please visit our Editors’ Pick here.